- 商品详情

- Comment

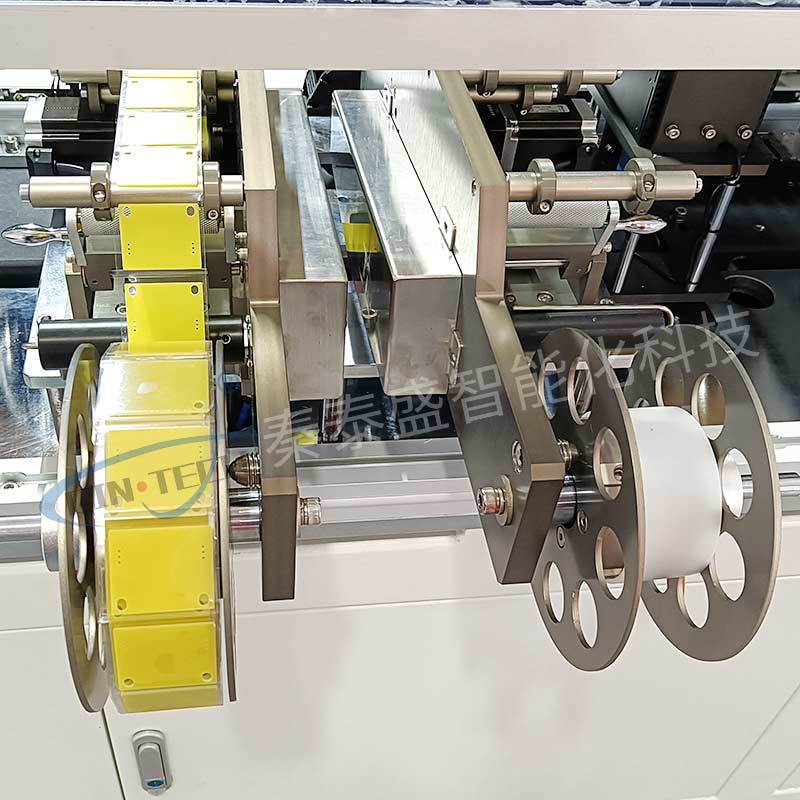

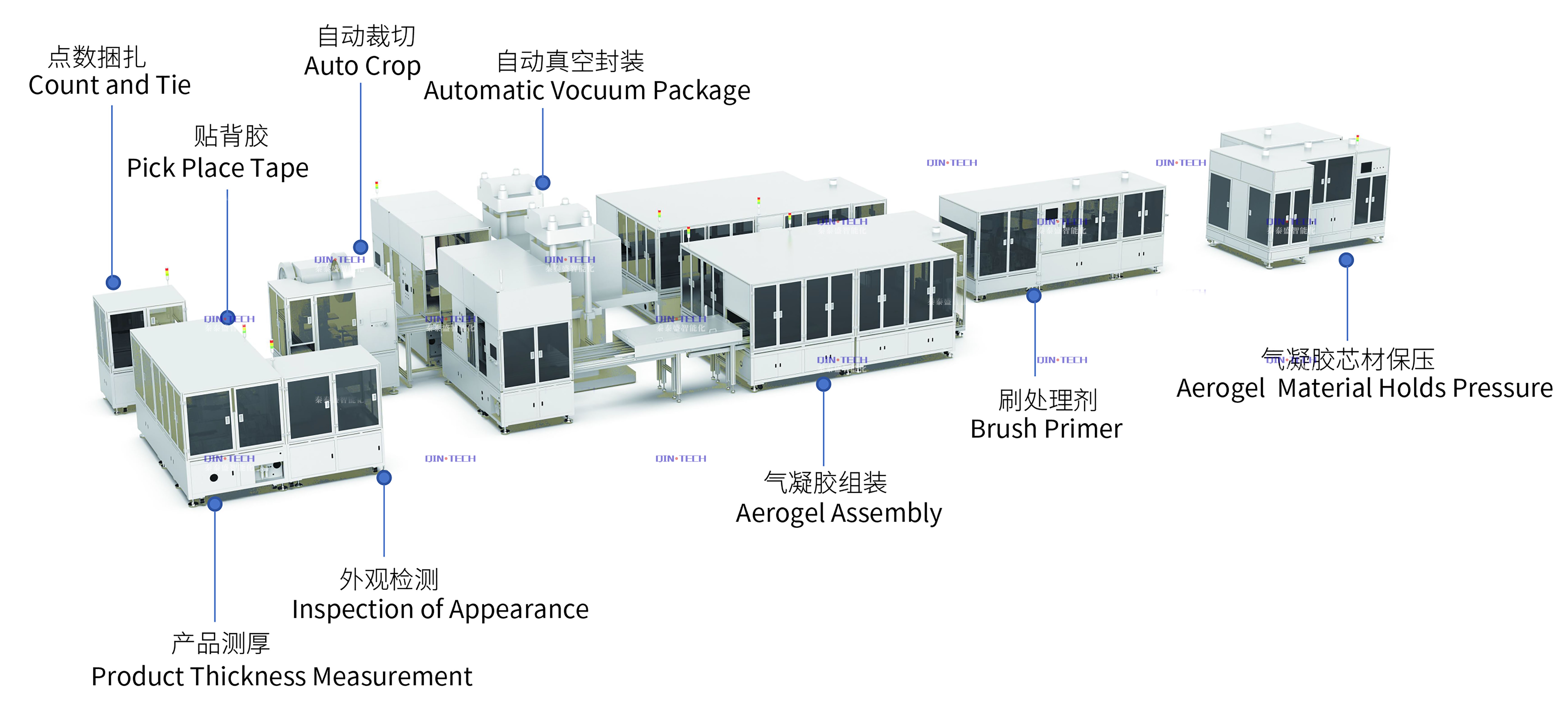

Qin-Tech Silicone-Framed Aerogel Encapsulation Automated Production Line: The entire line operates unmanned and requires no manual intervention (except for line changeover and material loading).

Line Features:

1. Product Dimension Range: L 100-250mm x W 100-200mm x H 1-10mm

2. Integrated Processes & Flexibility: The line integrates: aerogel core material pressure holding, primer brushing, aerogel assembly, automatic vacuum encapsulation, visual/thickness inspection, back adhesive application, and counting/bundling. Each unit is a flexible, stand-alone module that can be seamlessly connected for integrated line production or operate independently.

3. Key Specifications:

① Overall Line Capacity: ≥ 1,200 pieces per hour (PCS/H);

② Accuracy: Assembly Accuracy: ±0.2mm; Placement Accuracy: ±0.2mm;

③ False Rejection Rate: < 4%;

④ Equipment Failure Rate: < 4%;

⑤ Overall Line Yield Rate: ≥ 97%;

⑥ Operational Noise: < 75 dB;

⑦ Energy Efficiency: Designed to meet the first-class energy efficiency standard.

4. Customization: The production line can be custom-built (non-standard) according to specific customer requirements or within a compatible scope.

Copyright © 2017 Guangdong Qin Taisheng Intelligent Technology Co., Ltd.