- Details

- Comment

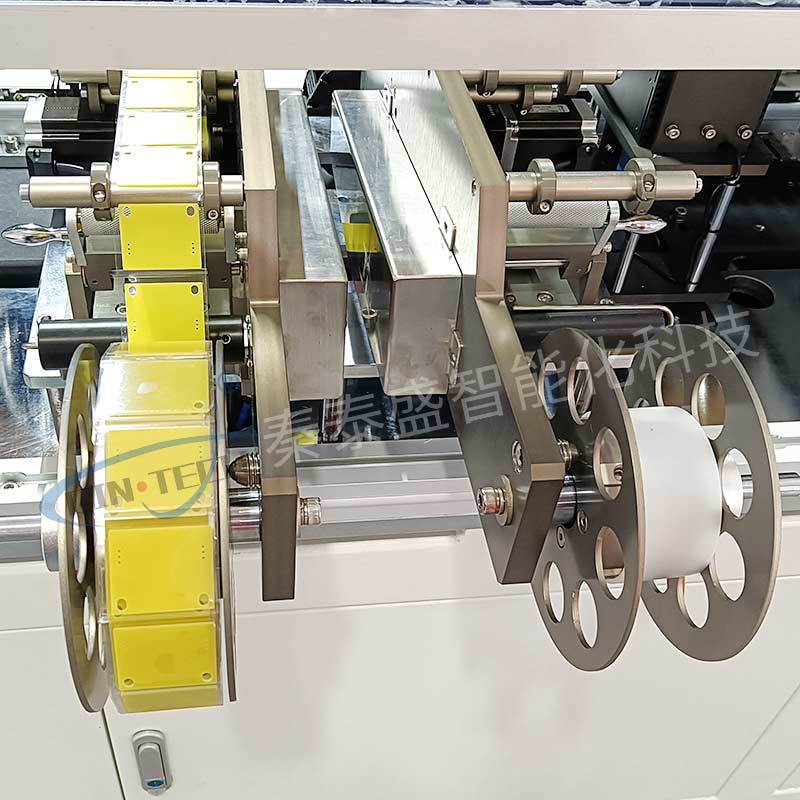

ATM-250C automatic auxiliary material labeling machine is a high-speed and high-precision labeling equipment specially designed for the electronic processing industry. This machine is used to attach single-sided adhesive label paper to the surface of the material. The single-track transmission is suitable for the customer's high-speed production line. This product is a computer control system specially tailored for SMT and SMD production workshops. The programming steps are intuitive and simple. , easy to operate, can help customers quickly improve product quality and production efficiency. Mainly used in FPC and PCB industry soft and hard boards in the electronics industry, mobile phones and other 3C industry screens and accessories on hardware and plastic shells.

1. Greatly improve the production line auxiliary material placement capacity;

2. Significantly reduce the error rate of the operator's accessories placement;

3. High speed: up to 3600 pieces/hour;

4. High precision: two sets of high-precision visual alignment elements up and down;

5. Flexible: optional task alignment, one-time alignment, and two-time alignment modes;

6. Wide adaptability: suitable for the application of various high-speed, high-precision labels and accessories;

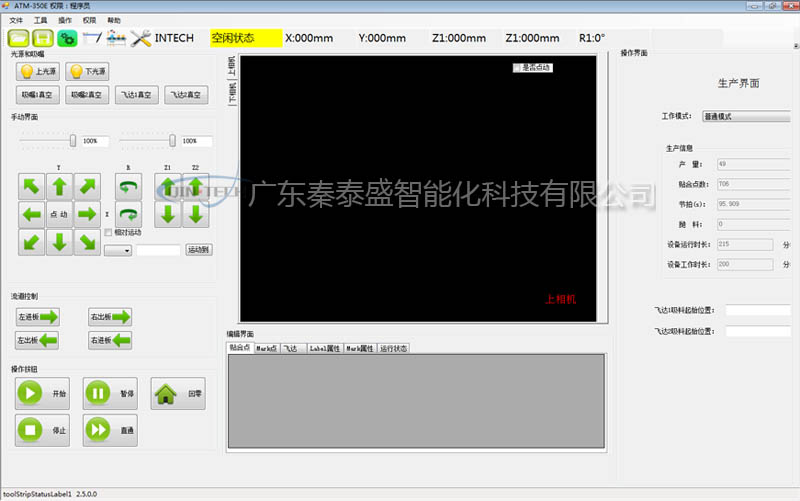

software interface

1. Open and save the software, select the interface, and select the permission to modify.

2. Device status, real-time coordinates of xyzr axis

3. Attachment mode selection, production information

4. Speed adjustment, XY axis on the left, ZR axis on the right

5. Manual operation direction movement

6. Runner inlet and outlet selection

7. Automatic production operation, start pause, return to zero and stop selection

8. Attached coordinate feeder coordinate operation information display

Dimensions | length*width*height | (1200*1350*1600mm) |

gross weight | 500kg | |

PCB circuit board | PCB board length and width | Min:300mm*250mm |

PCB board thickness | 1.0-5.0mm | |

PCB board fixing method | edge clamping | |

operating system | system | Win7 |

show | 19 inch LED display | |

input device | Mouse and keyboard | |

visual system | Number of cameras | 2 sets (1.3 million pixels) |

sticker identification | Grayscale and shape discrimination, feature comparison and edge computing | |

Labeling accuracy | ±0.1mm | |

Patch speed | 2500~3500PCS/H (best case) | |

Label range | L2mm*W4mm-L100mm*W4mm | |

Movement accuracy | The positioning accuracy of X, Y, Z axis is ±0.01mm, and the rotation positioning accuracy of U axis is ±0.5 degrees | |

Z axis maximum travel | 35mm | |

labeling header | double head | |

transfer track | Single-track two-section standard SMT track, labeling station has a top plate mechanism | |

Automatic adjustment of track width (maximum 250mm) | ||

Track height 900mm±30mm | ||

The number of feeders that can be placed | 2branch | |

using electric | Simplex(220AC±10%) 50Hz | |

Use air source | 0.5~0.6Mpa | |

Air source flow | 60L/min above | |

mains power | 1.9KW | |

Maximum current | 10A | |

Featured configuration | Labels and barcodes at any angle of 0-360° can be attached at will | |

Multiple labels can be attached to a single board or a multi-panel board at will | ||

Optional barcode automatic identification system | ||

Optional pass-through operation | ||

Standard SMEMA interface | ||

Copyright © 2017 Guangdong Qin Taisheng Intelligent Technology Co., Ltd.