- Details

- Comment

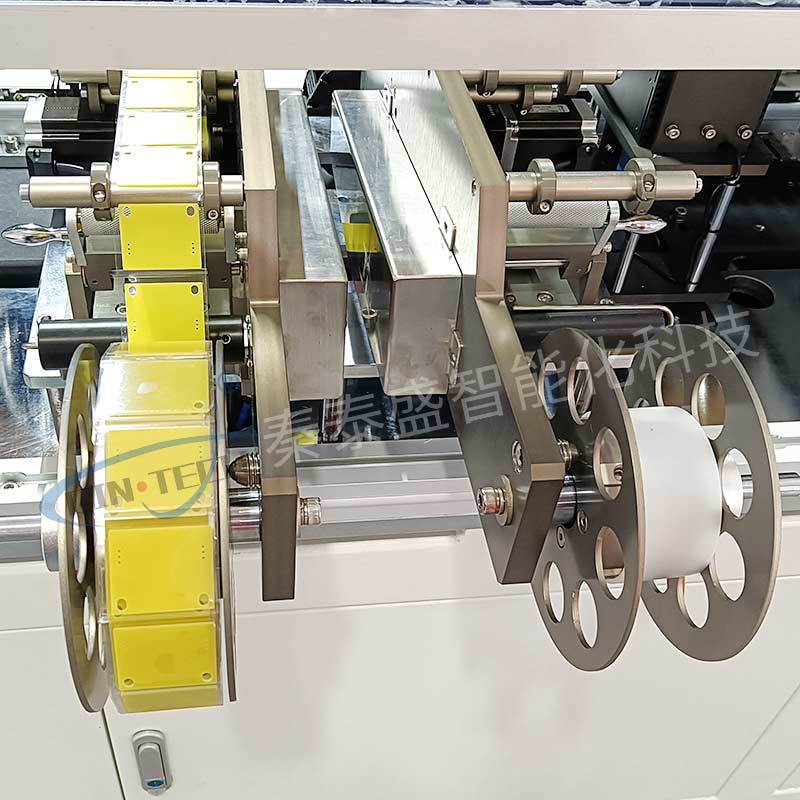

AMPM-3 automatic three-side sealing mask packaging machine

one. Main performance and structural features:

1. Double frequency conversion control/three servo control, the bag length can be set on the touch screen, no need to adjust the idling, one step, saving time and film.

2. Human-machine interface, automatic saving of parameter settings is convenient and quick.

3. Fault self-diagnosis function, fault display is clear at a glance.

4. High-sensitivity photoelectric eye color mark tracking, digital input of sealing and cutting position, so that the sealing and cutting position is more accurate.

5. Temperature independent PID control, suitable for various packaging materials.

6. Positioning stop function, no sticking to the knife, no waste of film.

7. The transmission system is simple, the work is more reliable, and the maintenance is more convenient.

8. All controls are realized by software, which is convenient for function adjustment and technical upgrade

two. Scope of application

Suitable for all kinds of flat masks, KF94, and other regular products.

3. Machine parameters

| Model | AMPM-3 |

| Film width | 350mm |

| Bag length | 150-280mm |

| Bag width | 30-150mm |

| Product height | ≤40mm |

| Diameter of film roll | ≤320mm |

| Packing speed | 40-180 Package/min |

| Power Specifications | 220V,50/60HZ,2.4KW |

| Machine size | (L)3770×(W)670×(H)1450 |

| Machine quality | about 450Kg 450Kg |

4. Main configuration list of electrical components:

机型 | AMPM-3 |

薄膜宽度 | 350mm |

制袋长度 | 150-280mm |

制袋宽度 | 30-150mm |

产品高度 | ≤40mm |

膜卷直径 | ≤320mm |

包装速度 | 40-180包/分 Package/min |

电源规格 | 220V,50/60HZ,2.4KW |

机器尺寸 | (L)3770×(W)670×(H)1450 |

机器质量 | 约450Kg 450Kg |

/

Copyright © 2017 Guangdong Qin Taisheng Intelligent Technology Co., Ltd.